Products

FeatureMILL3D includes all the functionality of FeatureMILL2.5D and FeatureRECOGNITION, plus powerful 3D programming capabilities.

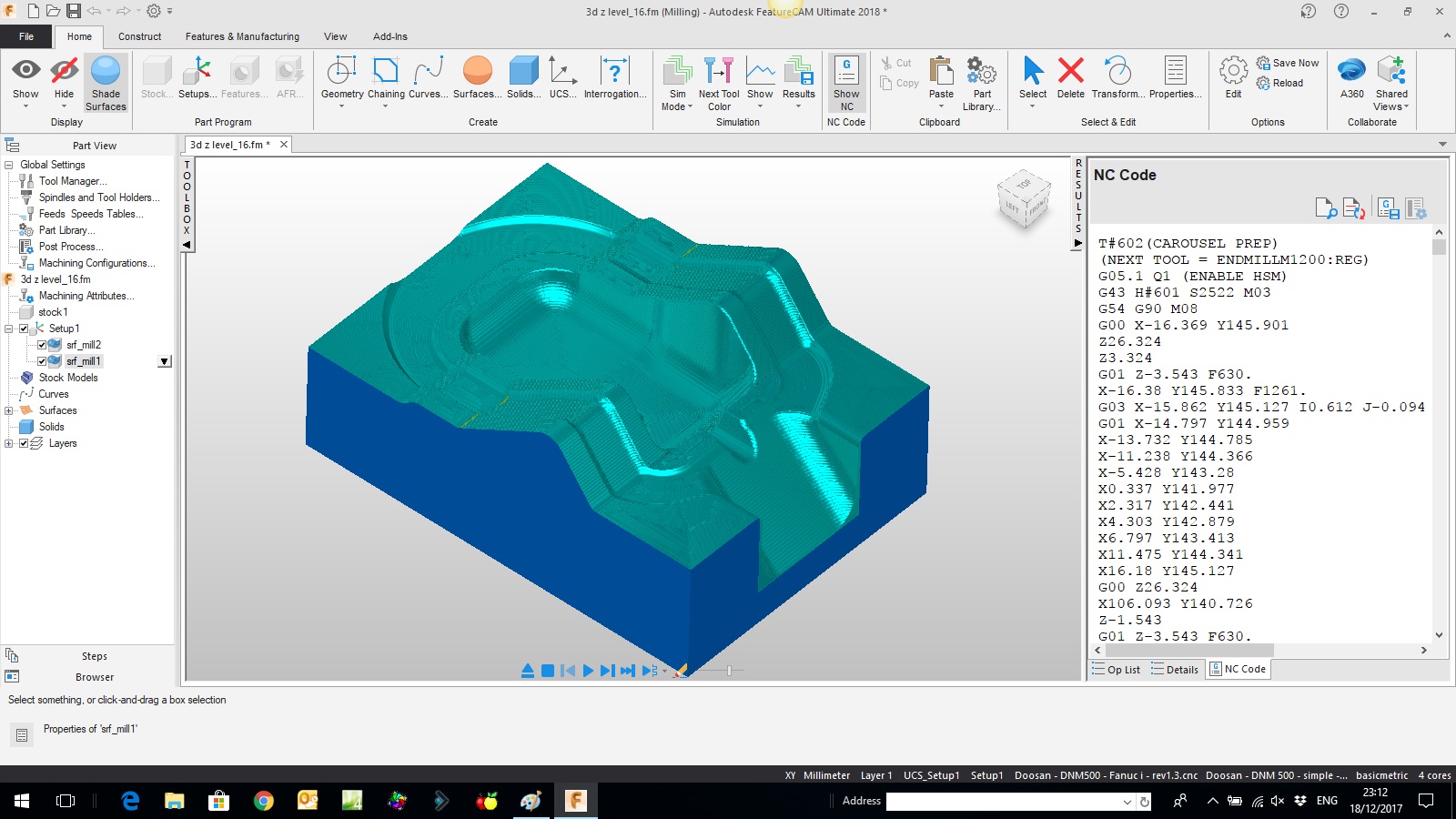

Determining a strategy for 3D cutting has never been easier! FeatureMILL3D's New Feature wizard walks you through roughing, semi-finishing, and finishing steps for 3D feature and toolpath creation. FeatureMILL3D also includes a surface milling wizard that allows you to specify options, boundaries, and slope limitations.

3D Manufacturing Techniques

FeatureMILL3D provides gouge-free toolpath generation in a unique 3D feature-based interface. You can create machining strategies for roughing and finishing multi-surface models using several techniques. Z Level, Radial, Parallel, Spiral, Isoline, Flowline, Pencil etc.

Interleaved Finish Toolpath

FeatureCAM's Interleaved Finish Toolpath uses a single pass technique to provide a superior finish on complex surfaces. With retract moves kept to a minimum, the tool stays on the metal and maintains smooth transitions for a faster and more productive toolpath.

Simulation

FeatureMILL3D provides additional simulation options to make verifying toolpaths quicker and easier.

RapidCut Simulation - With FeatureMILL3D's RapidCut simulation, you can view the results of 3D toolpaths in a matter of seconds, without waiting for the tool to animate. You can also use this feature to fast forward to specific toolpaths and then animate the tool to study certain toolpaths more closely.

Part Comparison - You can meet part tolerance requirements in less time with FeatureMILL3D's part comparison. FeatureMILL3D instantaneously compares the original part with the simulation. Areas with remaining material are shown in shades of blue and areas with gouging are shown in yellow, orange or red, according to the extent of the gouge. Green indicates areas that are cut within tolerance. You can change tolerance amounts to meet your specific requirements.

Telephone: 0116 267 5588